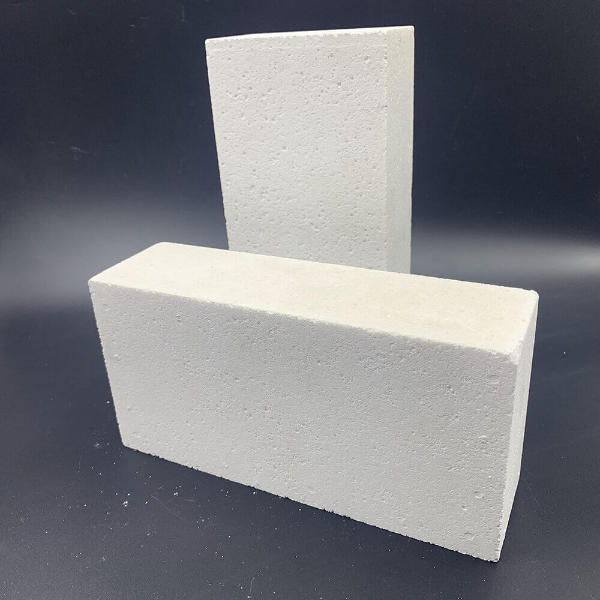

Alumina bubble brick is a high quality thermal insulation material, which can be used as a furnace lining as an insulating layer, which allows you to reduce the weight of the furnace body and optimize the furnace design. The fire resistance of alumina bubble brick can reach more than 1750 degrees, and thermal stability is good.

Parameters of Alumina Bubble Brick

| Subject | Index | ||

| LQZ99-1.4 | LQZ99-1.6 | LQZ99-1.8 | |

| Al2O3 % | ≥99 | ||

| SiO2 % | ≤0.3 | ||

| Fe2O3 % | ≤0.2 | ||

| Bulk density g/cm3 | 1.3~1.5 | 1.5~1.7 | 1.7~1.9 |

| Cold crush strength MPa | ≥6 | ≥10 | ≥12 |

| Thermal conductivity W/(m·K) Hot surface 1000℃ | ≤0.9 | ≤1.1 | ≤1.2 |

| Constant linear rate of change % 1600℃×3h | ±0.3 | ||

| Subject | Index | ||

| LQZ95-1.4 | LQZ95-1.6 | LQZ95-1.8 | |

| Al2O3 % | ≥95 | ||

| Fe2O3 % | ≤0.2 | ||

| Bulk density g/cm3 | 1.3~1.5 | 1.5~1.7 | 1.7~1.9 |

| Compressive strength at normal temperature MPa | ≥8 | ≥12 | ≥16 |

| Thermal conductivity W/(m·K) hot face 1000℃ | ≤0.9 | ≤1.1 | ≤1.2 |

| Constant linear change % 1600℃×3h | ±0.3 | ||

| Subject | Index | ||

| LQZ90-1.4 | LQZ90-1.6 | LQZ90-1.8 | |

| Al2O3 % | ≥90 | ||

| Fe2O3 % | ≤0.2 | ||

| Bulk density g/cm3 | 1.3~1.5 | 1.5~1.7 | 1.7~1.9 |

| Compressive strength at normal temperature MPa | ≥10 | ≥14 | ≥18 |

| Thermal conductivity W/(m·K) Hot face 1000℃ | ≤0.9 | ≤1.1 | ≤1.2 |

| Constant linear rate of change % 1600℃×3h | ±0.3 | ||

Advantages of Alumina Bubble Brick

- Low bulk density

- Low thermal conductivity

- Operating temperature above 1750℃

- High strength

- Withstands high temperature flames

- Saves energy

- Resistant to acid and alkaline corrosion

Advantages of Using Alumina Bubble Brick

In terms of cost, the price of heavy bricks and hollow ball bricks is the same, and the price of alumina hollow ball bricks for certain areas may be slightly higher, than heavy bricks. Nevertheless, in terms of weight, the use of hollow ball bricks reduces the cost per cubic meter. 1-2 tons. Moreover, no need to make an insulating layer, which reduces consumption and saves fuel. The effect of use is not only good, but the cost also decreases.

Applications of Aluminum Bubble Brick

Alumina bubble brick is a widely used thermal insulation material in furnaces, which plays a vital role in the construction and production of stoves. The bulk density of alumina bubble brick is small, which allows for a good reduction in the weight of the furnace body and has a good insulating effect, which saves energy and raw material costs.

About Rongsheng Group

Rongsheng Refractories Group

Rongsheng Refractories Group