Andalusite fire bricks use andalusite as raw material, add sillimanite powder, mullite powder and other powders, add binders according to the proportion and strictly control the particle size, grade and impurities, such as TiO2 and R2O raw materials. After melting, molding and drying it is fired at high temperatures, which can meet the needs of various parts and working conditions of modern hot blast blast furnaces, and plays an important role in increasing the service life of hot blast blast furnaces.

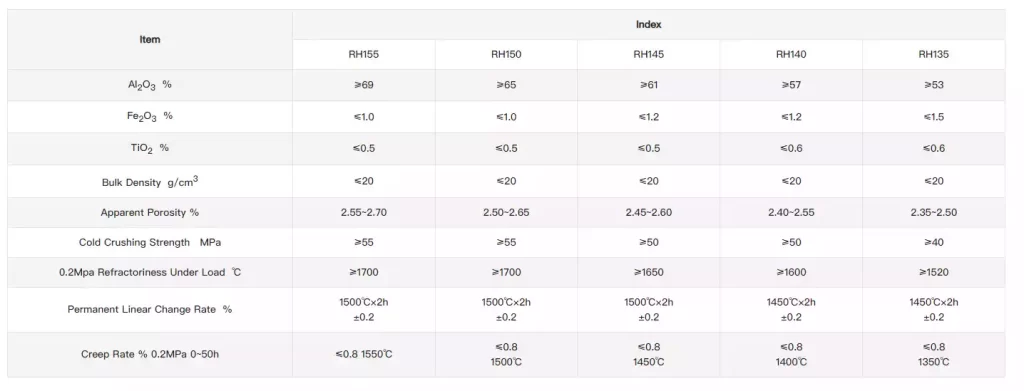

Physical and chemical characteristics of andalusite brick

Features of andalusite brick

- High temperature resistance, wear resistance and corrosion resistance.

- Good thermal shock resistance.

- Low creep rate.

- High softening point under load.

- Can reduce harmful contaminants.

- Good resistance to thermal peeling.

- Various characteristics

- Sufficient warehouse, delivery on time.

Raw materials of andalusite brick

Mullite powder, fine andalusite powder, fine sillimanite powder, clay, silicon micropowder, etc.. d.

Andalusite Fire Brick Manufacturing Process

Prepare raw materials according to formula ratio, then place mullite powder, fine andalusite powder and fine sillimanite powder into a sand mixer for mixing, then add clay and 2% from the total mass of raw materials for mixing, and then add silicon. Micropowder is mixed and pressed into adobe using a brick press. After the adobe has dried, it is placed in a kiln for sintering., that is, they burn andalusite refractory bricks.

Use of andalusite bricks in hot blast kilns

For hot blast furnace walls, checker bricks, stove roof, and combustion chamber(Low creep andalusite series).

Transporting andalusite bricks

After that, How will the factory receive the order?, it will be produced as soon as possible and shipped within 7-12 days. Custom products will take longer to produce.

Corresponding Certificate

Rongsheng Refractories Group

Rongsheng Refractories Group