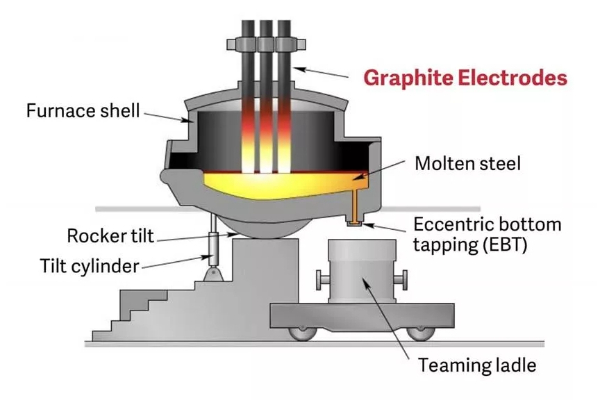

Graphite electrodes and nipples are important components, used in electric arc furnaces for the production of steel and other metals.

Graphite electrodes and nipples are critical components in the steelmaking process, as they play a crucial role in creating high temperatures, necessary for melting and refining metals. The quality and performance of the electrodes and nozzles are essential to the overall efficiency and productivity of the electric arc furnace, and therefore they must be manufactured to strict quality standards.

Graphite electrodes and pipe parts

Graphite electrode

| Subject | Nominal diameter mm | ||||||||||

| 75~130 | 150~225 | 250~300 | 350~450 | 500~800 | |||||||

| Class | Excellent | one | Ex | one | Ex | one | Ex | one | Ex | one | |

| Resistivity μΩ·m ≤ | Electrode | 8.5 | 10.0 | 9.0 | 10.5 | 9.0 | 10.5 | 9.0 | 10.5 | 9.0 | 10.5 |

| Connector | 8.0 | 8.0 | 8.0 | 8.0 | 8.0 | ||||||

| Flexural strength, MPa ≥ | Electrode | 10.0 | 10.0 | 8.0 | 7.0 | 6.5 | |||||

| Connector | 15.0 | 15.0 | 15.0 | 15.0 | 15.0 | ||||||

| Elastic modulus, GPa ≤ | Electrode | 9.3 | 9.3 | 9.3 | 9.3 | 9.3 | |||||

| Connector | 14.0 | 14.0 | 14.0 | 14.0 | 14.0 | ||||||

| Bulk density, g/cm3 ≥ | Electrode | 1.58 | 1.53 | 1.53 | 1.53 | 1.52 | |||||

| Connector | 1.70 | 1.70 | 1.70 | 1.70 | 1.70 | ||||||

| Thermal expansion coefficient 10-6/℃ room temperature ~600℃ ≥ | Electrode | 2.9 | 2.9 | 2.9 | 2.9 | 2.9 | |||||

| Connector | 2.7 | 2.7 | 2.8 | 2.8 | 2.8 | ||||||

| Ash % ≤ | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | ||||||

High Power Graphite Electrodes

| Subject | Nominal diameter mm | |||

| 200~400 | 450~500 | 550~700 | ||

| Resistivity μΩ·m ≤ | Electrode | 7.0 | 7.5 | 7.5 |

| Connector | 6.3 | 6.3 | 6.3 | |

| Flexural strength, MPa ≥ | Electrode | 10.5 | 10.0 | 8.5 |

| Connector | 17.0 | 17.0 | 17.0 | |

| Elastic modulus, GPa ≤ | Electrode | 14.0 | 14.0 | 14.0 |

| Connector | 16.0 | 16.0 | 16.0 | |

| Bulk density, g/cm3 ≥ | Electrode | 1.60 | 1.60 | 1.60 |

| Connector | 1.72 | 1.72 | 1.72 | |

| Thermal expansion coefficient 10-6/℃ Room temperature~600℃ ≥ | Electrode | 2.4 | 2.4 | 2.4 |

| Connector | 2.2 | 2.2 | 2.2 | |

| Ash % ≤ | 0.5 | 0.5 | 0.5 | |

Ultra High Power Graphite Electrode

| Subject | Nominal diameter mm | ||||

| 300~400 | 450~500 | 550~650 | 700~800 | ||

| Resistivity μΩ·m ≤ | Electrode | 6.2 | 6.3 | 6.0 | 5.8 |

| Connector | 5.3 | 5.3 | 4.5 | 4.3 | |

| Flexural strength, MPa ≥ | Electrode | 10.5 | 10.5 | 10.0 | 10.0 |

| Connector | 20.0 | 20.0 | 22.0 | 23.0 | |

| Elastic modulus, GPa ≤ | Electrode | 14.0 | 14.0 | 1.66 | 14.0 |

| Connector | 20.0 | 20.0 | 1.78 | 22.0 | |

| Bulk density, g/cm3 ≥ | Electrode | 1.67 | 1.66 | 1.66 | 1.68 |

| Connector | 1.74 | 1.75 | 1.78 | 1.78 | |

| Thermal expansion coefficient 10-6/℃ Room temperature~600℃ ≥ | Electrode | 1.5 | 1.5 | 1.5 | 1.5 |

| Connector | 1.4 | 1.4 | 1.3 | 1.3 | |

| Ash % ≤ | 0.5 | 0.5 | 0.5 | 0.5 | |

Application of graphite electrodes

Electric Arc Furnace for Electric Arc Furnace.

Used in ore-smelting electric furnaces.

Used in resistance furnaces

Used to make specially shaped graphite products.

Advantages of graphite electrodes

Corrosion resistance: Graphite electrodes have excellent corrosion resistance and can resist erosion by many strong acids, alkalis, solvents and other aggressive substances. This makes them suitable for many industrial processes with aggressive media..

High temperature stability: Graphite electrodes remain stable at high temperatures, which allows their use in high-temperature reactions and processes, such as electric arc furnaces, high temperature electrolysis, etc..

Conductive properties: Graphite is an excellent conductive material and can conduct electrical current effectively.

High mechanical strength: Graphite electrodes have high mechanical strength and hardness, which reduces the likelihood of deformation or breakage during use.

Ease of processing: Graphite is relatively easy to process into a variety of shapes and sizes and can be tailored to specific application needs.

Oxidation resistance: Graphite electrodes are particularly resistant to oxidation.

Transportation and delivery of graphite electrode

Introduction to Rongsheng company

Rongsheng is a professional fireproof material supplier with 10 years of export experience to more than 80 countries. Rongsheng's main products are various fire bricks, shapeless fireproof materials, metallurgical materials, thermal insulation materials and so on.

Rongsheng Refractories Group

Rongsheng Refractories Group