High alumina refractory brick is a silicic acid refractory material, softening temperature under load is 1420-1550°C, and the load temperature will increase with increasing ratio of aluminum and silicon.

Advantages of high alumina bricks

Bricks with high alumina content have good resistance to acid and alkali slags, corrosion and oxidation of molten metal, reducing reactivity, as well as good heat resistance, but lower, than clay.

Three grades of high alumina refractory bricks

- The Al2O3 content in high-alumina brick of the first grade is >75%.

- The Al2O3 content in secondary high-alumina brick is 60-75%.

- The Al2O3 content in high-alumina brick of the third grade is 48-60%.

high alumina refractory brick index

| Physico-chemical index of high alumina refractory bricks: | ||||||

| Subject | Properties | |||||

| RS-80 | RS-75 | RS-65 | RS-55 | RS-48 | ||

| Al2O3(%) | 80 | ≥75 | ≥65 | ≥55 | ≥48 | |

| fire resistance(°C ) | ≥1790 | ≥1790 | ≥1790 | ≥1770 | ≥1750 | |

| Bulk density(g/cm3) | 2.65 | 2.5 | 2.45 | 2.4 | 2.3 | |

| Softening temperature under load(°C ) | 1530 | ≥1520 | ≥1500 | ≥1470 | ≥1420 | |

| Linear reheat rate changes(%) | 1500°CX2H | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| 1450°CX2H | -0.4 | -0.4 | -0.4 | -0.4 | -0.4 | |

| Apparent porosity (%) | 22 | ≤23 | ≤23 | ≤22 | ≤22 | |

| Cold crush strength (Mpa) | 55 | ≥50 | ≥45 | ≥40 | ≥35 | |

Features of high alumina brick

- High fireproof temperature

- Good strength

- Chemical corrosion resistance

- Good thermal conductivity

- Long service life

- Wear-resistant

Application of high alumina bricks

High alumina brick is mainly used for blast furnace lining, hot blast furnaces, electric furnace roofs, blast furnaces, reverberatory kilns and rotary kilns.

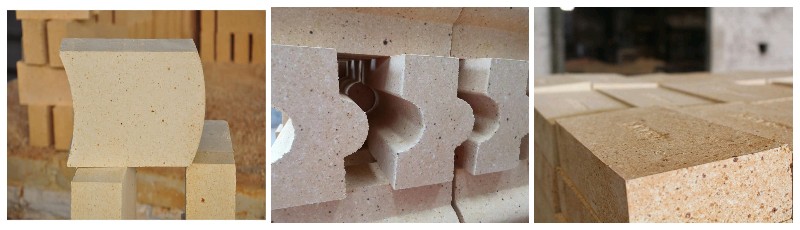

Customized Aluminum Fire Brick

Refractory material factory supports customized aluminum refractory brick manufacturing. You can send us the size or design drawings of your aluminum fire bricks, and we will appreciate them, and then we will draw up a production plan for you.

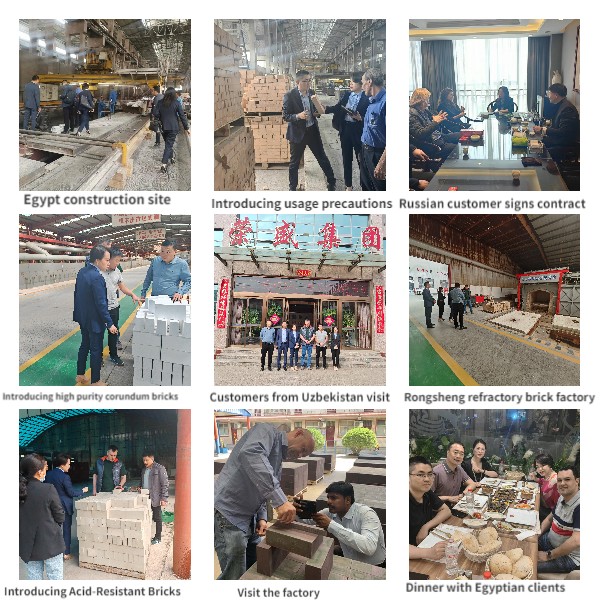

About Rongsheng Factory

About clients

Our factory welcomes buyers of refractory bricks and refractory materials to visit us. We will warmly welcome you. In the same time, if customers have needs, our technicians will also go to the customer's construction site, to provide recommendations, and are ready to solve practical difficulties for clients.

Get an offer

Rongsheng Refractories Group

Rongsheng Refractories Group