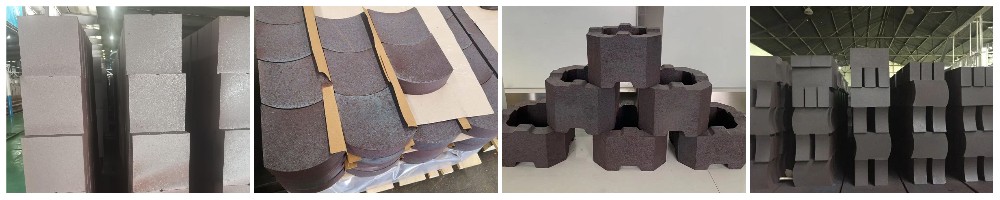

Chromium-magnesium brick is a refractory brick, the main components of which are magnesium oxide and chromium oxide, and the main mineral components are periclase and spinel. Fired at 1600–1800°C in an oxidizing atmosphere, It can also be used to make unfired bricks using chemical binders, such as liquid glass. Magnesia-chrome bricks have high fire resistance, strong corrosion resistance to alkali slags, good thermal stability and certain resistance to acidic slags.

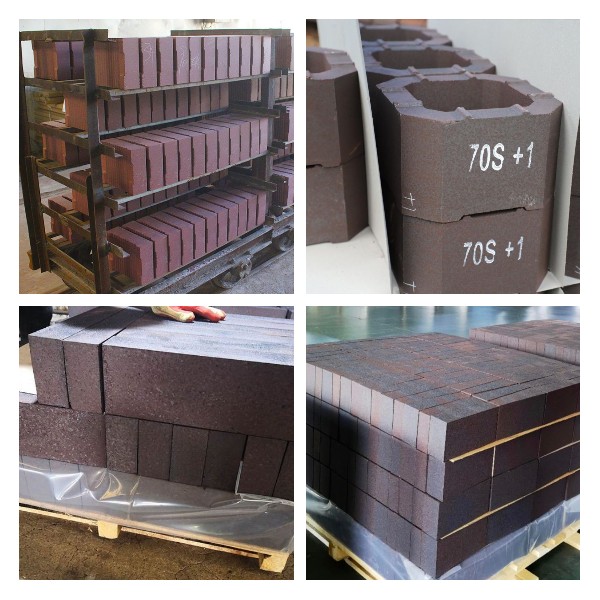

Production of magnesia-chrome bricks

The main raw materials for the production of magnesia-chrome bricks are sintered magnesia and chromite. In the process of producing magnesia-chrome bricks, the purity of magnesia raw materials must be high. The chemical composition standard for chrome ore is 30-45% Cr2o3, ≤ 1-1,5% Cao.

Composition of magnesia-chrome brick

- Ordinary sintered magnesium chrome bricks: The purity of the raw materials is low, lightly burned magnesia is used, and the sintering temperature is low.

- Magnesia-chrome bricks with direct connection: The raw materials are of high purity, dead-fired magnesia is used, and the sintering temperature of bricks in a tunnel kiln is higher, than conventional sintered magnesia-chrome bricks.

- Fused semi-recombined magnesia-chrome bricks: The raw materials are calcined magnesia and fused magnesia, and the sintering temperature is higher, than conventional sintered magnesia-chrome bricks.

- Fused and recombined magnesia chrome brick: The raw material is made from fused magnesia, and the cost is high.

Physico-chemical indicators of magnesia-chrome brick

Physico-chemical indicators of ordinary magnesia-chrome brick::

| Subject | Index | |||||

| MG-16A | MG-16B | MG-12A | MG-12B | MG-8A | MG-8B | |

| MgO % | ≥50 | ≥45 | ≥60 | ≥55 | ≥65 | ≥60 |

| Cr2O3 % | ≥16 | ≥16 | ≥12 | ≥12 | ≥8 | ≥8 |

| Apparent porosity % | ≤19 | ≤22 | ≤19 | ≤21 | ≤19 | ≤21 |

| Cold crush strength MPa | ≥35 | ≥25 | ≥35 | ≥30 | ≥35 | ≥30 |

| 0.2Mpa Fire resistance under load ℃ | ≥1650 | ≥1550 | ≥1650 | ≥1550 | ≥1650 | ≥1530 |

Physico-chemical indicators of fused semi-recombined magnesia-chrome brick::

| Subject | Index | |||

| ZMG-16A | ZMG-12A | ZMG-8A | ZMG-6 | |

| MgO % | ≥60 | ≥68 | ≥75 | ≥75 |

| Cr2O3 % | ≥16 | ≥12 | ≥8 | ≥6 |

| SiO2 % | ≤1.5 | ≤1.5 | ≤1.5 | ≤2.5 |

| Apparent porosity % | ≤18 | ≤18 | ≤18 | ≤18 |

| Cold crush strength MPa | ≥40 | ≥45 | ≥45 | ≥45 |

| 0.2Mpa Fire resistance under load ℃ | ≥1700 | |||

Physico-chemical indicators of fused semi-recombined magnesia-chrome brick :

| Subject | Index | |||

| BMG-26 | BMG-24 | BMG-22 | BMG-20A | |

| MgO % | ≥50 | ≥50 | ≥55 | ≥58 |

| Cr2O3 % | ≥26 | ≥24 | ≥22 | ≥20 |

| SiO2 % | ≤2.0 | ≤2.0 | ≤2.0 | ≤2.0 |

| Apparent porosity % | ≤16 | ≤16 | ≤16 | ≤16 |

| Cold crush strength MPa | ≥40 | ≥45 | ≥45 | ≥45 |

| 0.2Mpa Fire resistance under load ℃ | ≥1700 | |||

| Subject | Index | ||

| BMG-18 | BMG-16A | BMG-12A | |

| MgO % | ≥58 | ≥60 | ≥68 |

| Cr2O3 % | ≥18 | ≥16 | ≥12 |

| SiO2 % | ≤2.0 | ≤2.0 | ≤2.0 |

| Apparent porosity % | ≤16 | ≤16 | ≤16 |

| Cold crush strength MPa | ≥40 | ≥45 | ≥45 |

| 0.2Mpa Fire resistance under load ℃ | ≥1700 | ||

Physico-chemical characteristics of fused recombined magnesia-chromium brick::

| Subject | Index | |||||

| DMG-26 | DMG-24 | DMG-22 | DMG-20 | DMG-16 | DMG-12 | |

| MgO % | ≥50 | ≥50 | ≥55 | ≥58 | ≥62 | ≥68 |

| Cr2O3 % | ≥26 | ≥24 | ≥22 | ≥20 | ≥16 | ≥12 |

| SiO2 % | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 |

| Apparent porosity % | ≤16 | ≤16 | ≤16 | ≤16 | ≤16 | ≤16 |

| Cold crush strength MPa | ≥40 | ≥40 | ≥40 | ≥40 | ≥40 | ≥40 |

| 0.2Mpa Fire resistance under load ℃ | ≥1700 | ≥1700 | ≥1700 | ≥1700 | ≥1700 | ≥1700 |

Features of magnesia-chrome brick

- High frequency and low impurity content

- High temperature and softness

- High corrosion resistance

- Low porosity

- Long service life

- Not easy to wear out

- Production meets the standard

Temperature range of magnesia-chrome brick

The fire resistance of magnesia-chrome brick exceeds 2000°C, and the load softening temperature usually exceeds 1550°C. It has good volumetric stability at high temperatures and good resistance to rapid cooling and heating.

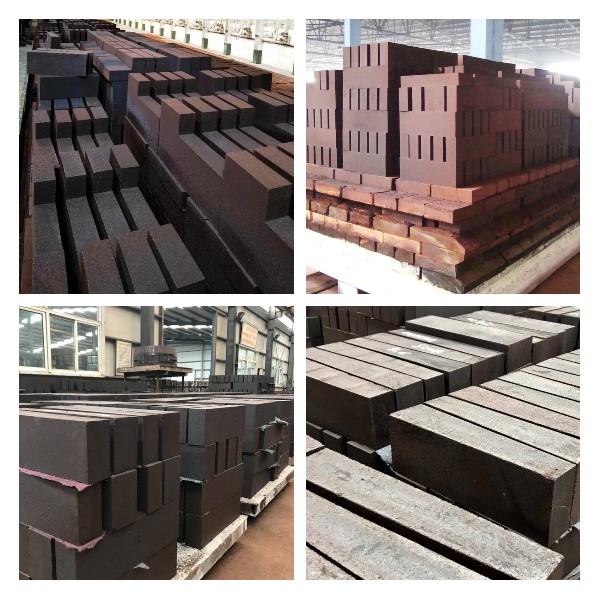

Scope of application of magnesia-chrome brick

Magnesia chrome brick can mainly be used in rotary cement kilns, glass furnace regenerators, lining of steel-smelting furnaces, permanent layer of refining ladles, non-ferrous metallurgy furnaces, lime kilns, mixed cast iron furnaces, lining of refractory high-temperature furnaces, etc..

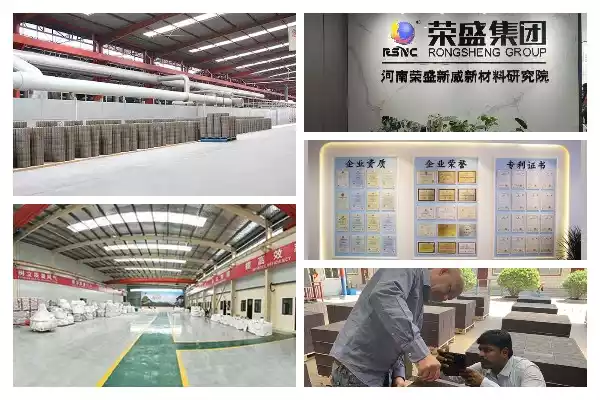

Fireproof Material Supplier Rongsheng

Rongsheng Refractories Group

Rongsheng Refractories Group