Mullite insulation brick is made from high alumina bauxite clinker as the base material plus a small amount of clay or raw bauxite as the binder, and then molded and sintered at high temperatures.

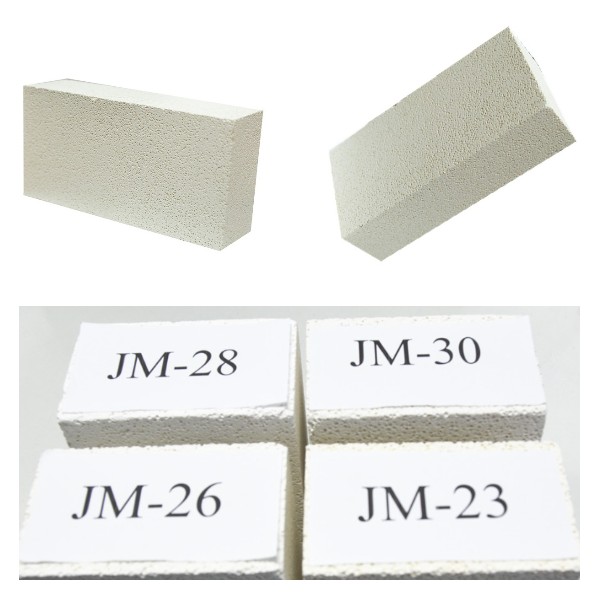

Mullite refractory brick is also called lightweight mullite brick and mullite thermal insulation brick. Mullite insulation brick is a high alumina refractory material with mullite (3Al2O3 2SiO2) as the main crystalline phase. Typically the aluminum oxide content is between 40% to 75%. They, with lower aluminum content, also contain small amounts of glass phase and cristobalite, and those, with higher alumina content, also contain small amounts of corundum.

Parameters of mullite-insulating bricks

Physical and chemical indicators:

| Subject | Index | ||||

| JM23 | JM25 | JM26 | JM27 | ||

| Al2O3 % | ≥40 | ≥50 | ≥55 | ≥60 | |

| Fe2O3 % | ≤1.0 | ≤1.0 | ≤0.9 | ≤0.8 | |

| Apparent porosity % | ≤0.55 | ≤0.80 | ≤0.85 | ≤0.9 | |

| Cold crush strength MPa | ≥1.0 | ≥1.5 | ≥2.0 | ≥2.5 | |

| Constant linear rate of change % | 1230℃×12h | 1350℃×12h | 1400℃×12h | 1450℃×12h | |

| -1.5~0.5 | |||||

| Thermal conductivity W/(m·K) | 200±25℃ | ≤0.18 | ≤0.26 | ≤0.28 | ≤0.32 |

| 350±25℃ | ≤0.20 | ≤0.28 | ≤0.30 | ≤0.32 | |

| 600±25℃ | ≤0.22 | ≤0.30 | ≤0.33 | ≤0.36 | |

| 0.05MPa Fire resistance under loadT0.5 ℃ | ≥1080 | ≥1200 | ≥1250 | ≥1300 | |

| Subject | Index | |||

| JM28 | JM30 | JM32 | ||

| Al2O3 % | ≥65 | ≥70 | ≥77 | |

| Fe2O3 % | ≤0.7 | ≤0.6 | ≤0.5 | |

| Apparent porosity % | ≤0.95 | ≤1.05 | ≤1.35 | |

| Cold crush strength MPa | ≥2.5 | ≥3.0 | ≥3.5 | |

| Constant linear rate of change % | 1510℃×12h | 1620℃×12h | 1730℃×12h | |

| -1.5~0.5 | ||||

| Thermal conductivity W/(m·K) | 200±25℃ | ≤0.35 | ≤0.42 | ≤0.56 |

| 350±25℃ | ≤0.37 | ≤0.44 | ≤0.60 | |

| 600±25℃ | ≤0.39 | ≤0.46 | ≤0.64 | |

| Fire resistance under load 0.5 ℃ | ≥1360 | ≥1470 | ≥1570 | |

Advantages of mullite-insulating bricks

- Low temperature synthesis

- Low thermal conductivity

- High fire resistance

- Good chemical stability

- High compressive and flexural strength

- Exact appearance and size

Application of mullite insulation brick

Mullite insulation brick is suitable for cracking furnace lining, blast furnaces, ceramic roller kilns, electric pull-out porcelain kilns, glass crucibles and various electric furnaces. It is used for the roof of the air heater, furnace bodies and hearths of blast furnaces, glass furnace regenerator, furnaces for sintering ceramics, lining of furnaces for oil cracking systems, etc.. d. Mullite insulation bricks also have softening characteristics under high loads. temperature, compact structure, low porosity and good erosion resistance.

Mullite Insulated Fire Brick Company

Success Case in Making Insulating Fire Bricks

Rongsheng Group's refractory bricks are sold in more than 80 countries, including Russia, Uzbekistan, Ecuador, Chile, South Africa, Portugal and other countries. Buyers are very happy with this JM mullite brick.

Frequently Asked Questions About Mullite Fire Bricks

The operating temperature range of mullite insulation bricks is generally 1000°C-1650°C and can be customized according to specific usage requirements.

Yes, customization support.

Store in a dry and ventilated warehouse to avoid moisture ingress. Be careful during transportation, to avoid strong vibration and collision, to avoid damage.

Rongsheng Refractories Group

Rongsheng Refractories Group