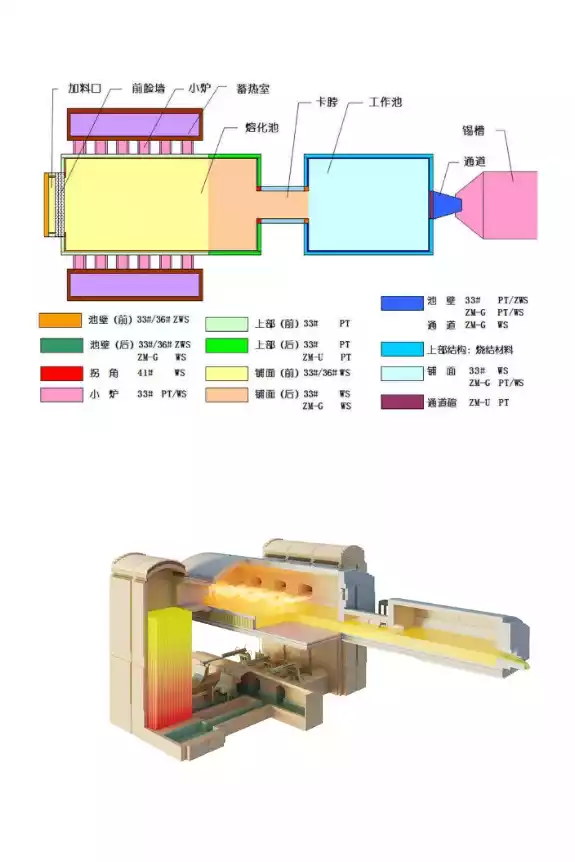

Float glass furnace

Float glass furnace refractories for every part

1.L-shaped hanging wall

Sand-lime brick

2.Melting part

Fused Silica Brick

3.Stuck neck

Sand-lime brick

4.cooling unit

Corundum refractories, sand-lime brick

5.Annealing furnace, conditioner

High alumina bricks, clay bricks, straight bond magnesia-chrome bricks.

Sand-lime brick

Sand-lime bricks widely used in glass melting furnaces, and the main component is silicon dioxide (SiO₂). The maximum operating temperature is about 1600-1650℃, and the working temperature of sand-lime brick is approximately 200 ℃ higher, than a clay adobe, but the erosion resistance of glass liquid and alkali volatile materials is poor, therefore it is used for the construction of large arches, parapets, small ovens and other structures. When constructing masonry, high-silicon refractory mortar or silicate brick powder and other substances should be used as binding materials., similar in composition to sand-lime brick.

| Subject | Index |

| SiO2 % | ≥98 |

| Al2O3 % | ≤0.3 |

| Fe2O3 % | ≤0.5 |

| CaO % | ≤0.2 |

| Bulk density g/cm3 | ≥1.8 |

| Apparent porosity % | ≤20 |

| Cold crush strength MPa | ≥30 |

| 0.2Mpa Fire resistance under load ℃ | ≥1650 |

| Thermal expansion coefficient % 1000℃ | ≤0.2 |

| Thermal shock resistance cycle water cooling at 1100℃ | ≥30 |

Clay brick

In the glass industry, Clay brick used to make the bottom of the furnace. Walls of the working part of the pool and passage, regenerator walls, walls, bottom facing brick and chimney. As the temperature increases, the volume of clay bricks will also increase. When the temperature exceeds 1450 °C, the volume will decrease again.

| Subject | Index |

| Al2O3 % | ≥45 |

| Fe2O3 % | ≤1.3 |

| Bulk density g/cm3 | ≥2.3 |

| Apparent porosity % | ≤16 |

| Cold crush strength MPa | ≥65 |

| Creep rate % 1200℃×50h | ≤0.05 |

| Thermal shock resistance cycle water cooling at 1100℃ | >10 |

High alumina brick

Outstanding Features high alumina brick have high fire resistance and a high softening point. It is similar to clay refractory materials. High alumina bricks can be used to construct the cooling basin wall of a glass furnace, the walls of the regenerator and the walls of the regenerator as a whole.

| Physico-chemical index of high alumina refractory bricks: | ||||||

| Subject | Properties | |||||

| RS-80 | RS-75 | RS-65 | RS-55 | RS-48 | ||

| Al2O3(%) | 80 | ≥75 | ≥65 | ≥55 | ≥48 | |

| fire resistance (°C ) | ≥1790 | ≥1790 | ≥1790 | ≥1770 | ≥1750 | |

| Bulk Density (g/cm3) | 2.65 | 2.5 | 2.45 | 2.4 | 2.3 | |

| Softening temperature under load (°C ) | 1530 | ≥1520 | ≥1500 | ≥1470 | ≥1420 | |

| Ramp rate during reheating (%) | 1500°CX2H | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| 1450°CX2H | -0.4 | -0.4 | -0.4 | -0.4 | -0.4 | |

| Apparent porosity (%) | 22 | ≤23 | ≤23 | ≤22 | ≤22 | |

| Cold crush strength (Mpa) | 55 | ≥50 | ≥45 | ≥40 | ≥35 | |

Mullite bricks

Mullite bricks have a fire resistance of about 1850°C, high softening temperature under load, low creep rate at high temperatures, good resistance to thermal shock and acid slag erosion. They can be selected as the bottom structure of the vertical chimney and the inner surface of the horizontal chimney. . Mullite is mainly used for pool wall masonry, inspection holes, wall chimneys, etc..

| Subject | IN THE 60'S | IN 65 | IN THE 70'S | IN 75 | |

| Chemical composition | Al2O3 | ≥60 | ≥65 | ≥70 | ≥75 |

| SiO2 | ≤35 | ≤33 | ≤26 | ≤24 | |

| Fe2O3 | ≤1.0 | ≤1.0 | ≤0.6 | ≤0.4 | |

| Apparent porosity% | ≤17 | ≤17 | ≤17 | ≤18 | |

| Bulk density g/cm3 | ≥2.55 | ≥2.55 | ≥2.55 | ≥2.55 | |

| Cold crush strength Mpa | ≥60 | ≥60 | ≥80 | ≥80 | |

| 0.2Mpa Fire resistance under load T0.6℃ | ≥1580 | ≥1600 | ≥1600 | ≥1650 | |

| Constant linear change when reheating (%)1500℃X2h | 0~+0.4 | 0~+0.4 | 0~+0.4 | 0~+0.4 | |

| Thermal resistance under 100℃ water cycles | ≥18 | ≥18 | ≥18 | ≥18 | |

| Constant linear change when reheating(%)1500℃X2h | 0.6 | 0.6 | 0.6 | 0.55 | |

| Cold crush strength Mpa | 1.74 | 1.84 | 1.95 | 1.95 | |

Fused zirconium corundum brick

Fused zirconium corundum bricks used for embedding into pool walls, flame space parapets, spouts of small stoves, low level dampers for furnaces, chimneys of small stoves, reed flaps, etc.. Fused zirconium-corundum bricks containing zirconium 41% used for lining the corners of the stone wall of the pool, holes for drainage of liquid and other parts, where the glassy liquid most strongly destroys the refractory material. This material is the most widely used fused cast refractory in the glass industry.

| Subject | Fused cast AZS brick | |||

| Index | RS-AZS33 | RS-AZS36 | RS-AZS41 | |

| Chemical composition % | Al2O3 | ≥50.00 | ≥49.00 | ≥45.00 |

| ZrO2 | ≥32.50 | ≥35.50 | ≥40.50 | |

| SiO2 | ≤15.00 | ≤13.50 | ≤12.50 | |

| Na2O+K2O | ≤1.30 | ≤1.35 | ≤1.30 | |

| Bulk density g/cm3 | ≥3.75 | ≥3.85 | ≥4.00 | |

| Apparent porosity % | ≤1.2 | ≤1.0 | ≤1.2 | |

| Cold crushing strength Mpa | ≥200 | ≥200 | ≥200 | |

| Glass phase exudation temperature | ≥1400 | ≥1400 | ≥1410 | |

| Bubble separation ratio(1300℃×10h) | ≤1.2 | ≤1.0 | ≤1.0 | |

| Anti-corrosion ability of glass liquid 1500℃×36h (mm/24h)% | ≤1.4 | ≤1.3 | ≤1.2 | |

| Bulk density(g/cm3) | Regular casting PT(RN RC N) | ≥3.55 | ≥3.55 | ≥3.70 |

| No shrinking ZWS casting(RR EVF EC ENC) | ≥3.65 | ≥3.75 | ≥3.85 | |

| QX casting tilt(RO) | ≥3.65 | ≥3.75 | ≥3.90 | |

| Shrink-free casting WS( RT VF EPIC FVP DCL) | ≥3.75 | ≥3.80 | ≥3.95 | |

Rongsheng Refractories Group

Rongsheng Refractories Group