Application of Aluminosilicate Ceramic Fiber Board

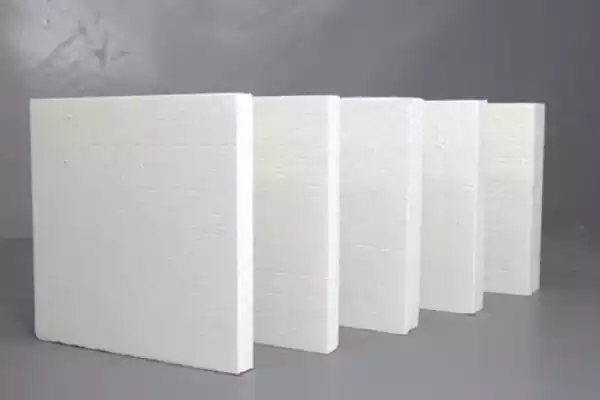

Aluminosilicate Ceramic Fiber Plate – this is fibreboard, used for thermal insulation and capable of maintaining good mechanical strength even when heated.

What is ceramic fiber?

Ceramic fiber, also known as aluminosilicate, is a fibrous lightweight fireproof material with high heat resistance, low thermal conductivity and miniature thermal melting.

Production Principle of Ceramic Fiberboard

Fiber is used as a raw material for the production of ceramic fiberboards, a certain proportion of binder and additives are added at the filler level, and it is completely dispersed into a suspension in a container for mixing the suspension using a mixer. Pump into the molding bath and mix with compressed air. Place the mold into the molding tank and use the vacuum principle, so that the fibrous suspension is adsorbed on the mold.

Precisely control adsorption time, dry wet fibrous material under vacuum, remove the mold, place it on a tray and place it in the drying oven for 10-24 o'clock. The dried fiberboard is passed through a grinder and edger for precise size control. Thus, The size of ceramic fiber board can be customized.

Properties of ceramic fiber board

In addition to the superior performance characteristics of matching loose ceramic fiber cotton, Ceramic fiber board has a hard texture, excellent toughness and strength, as well as excellent resistance to wind erosion. It does not expand when heated, has little weight, convenient in design and can be cut and bent as desired. It is an ideal energy-saving material for stoves, pipelines and other insulating equipment.

Advantages of Aluminosilicate Ceramic Fiber Board

- High compressive strength and long service life.

- Low heat capacity, low thermal conductivity.

- Not brittle material, good impact strength.

- Accurate size and good flatness.

- Easy to cut and install, convenient for construction.

- Excellent resistance to wind erosion.

- Continuous production, uniform fiber distribution and stable performance.

- Non-brittle material with low heat capacity and low thermal conductivity.

- Good elasticity, resistance to wind erosion and long service life.

- High thermal stability, high resistance to thermal shock and good tamper resistance.

Ceramic fiber industry

It is used as furnace lining, thermal insulation, compensators, heat separation and fire protection of each temperature zone of steel mills, metallurgical, oil, chemical, ceramic machines, non-ferrous metals, glass and other industrial furnaces.

What are the common ceramic insulating materials?

Common ceramic insulation materials include ceramic fiber blankets, ceramic fiber rope, ceramic fiber paper and ceramic fiber fabric. Depending on the application, different ceramic insulating materials are used.

Rongsheng Refractories Group

Rongsheng Refractories Group