Introduction of ladle refractory materials

The ladle is an important piece of continuous casting equipment. It is a container for transporting and holding molten steel from tapping to casting. A spoon is also called a ladle, which transports molten steel and refines it outside the furnace. Refractory materials, used in various bucket designs, also different. The following is a detailed introduction to refractory materials for ladles.

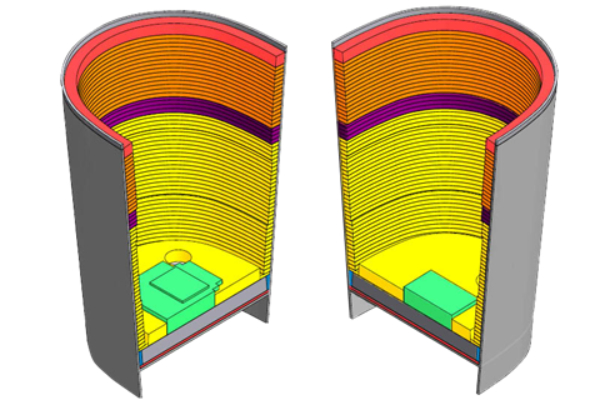

Bucket design

The ladle consists of a barrel body, linings, devices for opening and closing nozzles and ventilation units. Externally and internally, the internal lining consists of three layers: thermal insulation layer, middle layer and working layer; материальной части, соплового устройства, посадочного кирпича, breathable bricks and other parts.

Fireproof ladle bottom material

The refractory material at the bottom of the ladle is clay brick, also known as sintered brick, which is an artificial small block for construction. Clay brick uses clay (including slate, coal rock and other powdery materials) as main raw material, it is treated with a solution, molded and dried. And fried, are solid and hollow respectively.

The working layer of the ladle is made of refractories

Refractory high alumina bricks for the working layer of the ladle among refractory materials, produced from aluminum-silicon raw materials, bricks with Al203 as the main component include high alumina bricks, mullite bricks and corundum bricks.

Pouring the bucket body

Casting materials for ladles belong to the mixture, consisting of fire-resistant fillers, binders and additives, which mix with water (or liquid binders) for the formation of drilling fluids, which can be made by casting. The difference from other shapeless refractory materials is that, that refractory castings have a certain setting and hardening time after production, therefore a certain curing period is required after casting and molding, before they can be molded, and then after an appropriate period of natural hardening they can be sent out for baking. Use on the grill.

Refractories for ladle walls

Unfired brick, also known as chemically bonded brick. Refers to fireproof material, which can be used directly for masonry without firing bricks. Its production process is relatively simple. It uses fireproof materials from various materials. The combination of powder and granules in the product is mainly formed as a result of the chemical action of the binder.

Ladle for refined refractories

If the ladle is also used for refining, it can also be used for fireproof materials: zircon bricks, magnesia-carbon bricks, aluminum-magnesia-carbon bricks, magnesia-chrome bricks, magnesium-chromium-aluminum bricks, etc..

Rongsheng Refractories Group

Rongsheng Refractories Group