Problems and Solutions with Sliding Bucket Attachment

Due to certain defects in the original scoop nozzle system, used in a steel mill, the reliability of the sliding mechanism was low, and sliding blocks for casting steel were used only once. This not only increases the labor intensity of workers and the number of replaceable buckets, but does not contribute to an increase in the temperature of the ladle, and also causes high consumption of refractory materials in the filling system.

Problems with the bucket extension system

Bucket sliding plate hole

The diameter of the bucket sliding plate is less than 50 mm. Due to the large diameter, the sliding plate needs to be opened and closed many times during the casting process. Severe erosion of the sliding plate occurs after use, and the phenomenon of steel pulling between the surfaces of the sliding plate occurs, which cannot meet the requirements of continuous use.

Bucket sliding plate material

With the increase in steel varieties and the improvement in the quality of molten steel, various alloys need to be added in the steelmaking process, which leads to an increase in content [Ca ], [Mn ] in molten steel and CaO, MnO in steel slag. When aluminum-carbon or aluminum-zirconium-carbon sliders are used to cast these steels, melting loss at the edge of the slider hole is obvious.

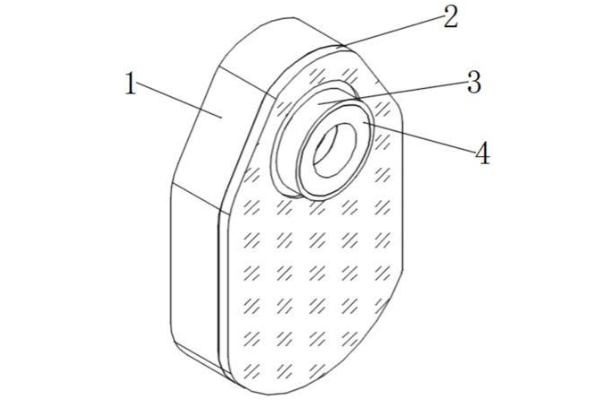

Bucket sliding mechanism

Spring, used for bucket sliding mechanism, used in high temperature conditions for a long time, and sometimes it can become deformed and fail, even if its service life has not expired. When the line is running, steel can wear away throughout the body.

Measures to improve the bucket sliding attachment

Changing the Slide Plate Hole Size

In accordance with the theoretical calculation, it was decided to change the diameter of the sliding plate hole from <50 mm on <40 mm i <45 mm, and a usage test was carried out. The test proves, that the sliding plate with the hole diameter <45 mm can not only meet the yield requirements of steel, but also meet the requirements of continuous use of the sliding plate, And, finally, defines, what is the diameter of the sliding plate hole for the bucket, used for harvesting, amounts to <45 mm.

Material selection

Change the material of the skateboard. Skateboard raw material is corundum as filler, aluminum metal powder as matrix and suitable additives are added. The mixture melts aluminum metal at the appropriate temperature, moderately nitrided and fired.

Rongsheng Refractories Group

Rongsheng Refractories Group