Introduction of magnesia carbon brick production process

Magnesium carbon bricks are heat-resistant fireproof material, mainly used for lining high temperature furnaces. Mgo-c bricks can be used in converters, electric arc furnaces, ladles and other parts and are an important refractory material for furnaces.

Magnesia-carbon bricks have these characteristics, like heat resistance, high slag resistance, good thermal shock resistance and low creep at high temperatures. The main components of magnesia-carbon bricks are magnesia and carbon. Below is the specific production process of magnesia carbon bricks:

Two ways to make magnesium carbon bricks

There are two ways to make magnesia-carbon bricks: burned, oil-impregnated magnesia-carbon brick and unfired magnesia-carbon brick. The first method of making bricks is more complex and is rarely used. Below is the production method of unfired magnesia carbon brick.

Graphite is added to the ingredients

Quality and quantity of graphite, added to ingredients, is critical. Generally speaking, increasing the graphite content in the refractory brick will increase the resistance to slag formation and thermal shock of the refractory brick, but strength and oxidation resistance will decrease. If the carbon content of magnesia carbon bricks is too low (<10%), if a mesh frame cannot be formed in the refractory brick, carbon benefits cannot be effectively used. Hence, carbon content is more acceptable in the range 10-20%.

Mixing raw materials to produce magnesium carbon bricks

During the mixing process, so that the graphite evenly surrounds the magnesia particles, The serving sequence should be as follows: magnesia particles → binder → graphite → fine magnesia powder and additive powder. Due to the high graphite content, low density and very small amount of additives requires a lot of time for uniform mixing, but if the mixing time is too long, graphite and fine powder around magnesia particles will easily fall off, therefore the mixing time must be appropriate.

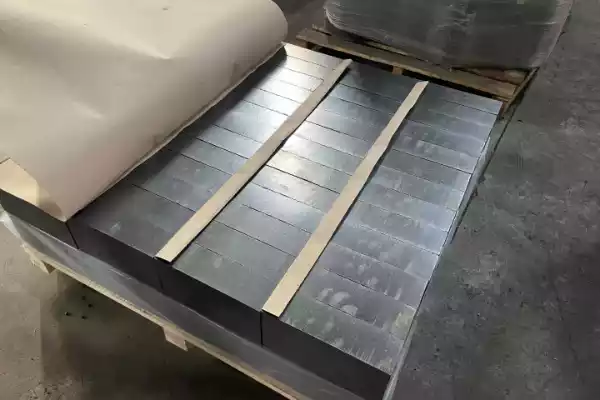

Molding of magnesia carbon brick

MgO-C brick molding is an important factor to make the refractory brick structure compact: quality and quantity of graphite, added to ingredients, very important. Due to the large amount of graphite in the drilling fluid and the small critical aggregate particles, it is recommended to use high pressure molding and press it strictly according to operating procedures: light weight first, then strong pressure and repeated presses, to avoid the formation of cracks. It is better to adhere to such operating procedures, like a vacuum cleaner, pumping out air and increasing pressure. Besides, adobe surface, high pressure molded, very smooth, and it slides easily during transportation and construction. Therefore, molded adobe should be impregnated or coated with a thermoset resin to a thickness of 0,1-2 mm for the formation of a polymer film, anti-slip. This treatment is usually called anti-slip treatment.

Heat treatment of MgO-C brick

Molded magnesium carbon adobe must be cured before it is used, and the curing temperature has a great influence on the performance characteristics of refractory bricks. Research has proven, that curing treatment at a temperature of 200-250°C is more suitable, which is good for ensuring the bulk density of bricks and reducing porosity. At temperatures above 250°C or below 200°C, the hardening treatment will cause adverse effects. It is necessary to strictly control the air temperature. Typically at a temperature of 50-60°C, due to resin softening, it should be kept properly warm; at a temperature of 100-110°C, because a large amount of solvent is released, it should be kept warm; at a temperature of 200-250°C, to complete the reaction, it should also be properly kept warm.

Rongsheng Refractories Group

Rongsheng Refractories Group