Application of refractories in a side-blow furnace for blister copper smelting

The side blow furnace is a device for rough smelting of copper.. Oxygen-enriched air is supplied to the furnace through primary tuyeres in the slag line area and reacts under the influence of high temperature. Blister copper is lowered below the molten bath and taken to the electric furnace. Collected at the top of the melt pool, it is discharged into the electric furnace through an overflow, and the corresponding flue gas is discharged from the chimney into gas for the boiler.

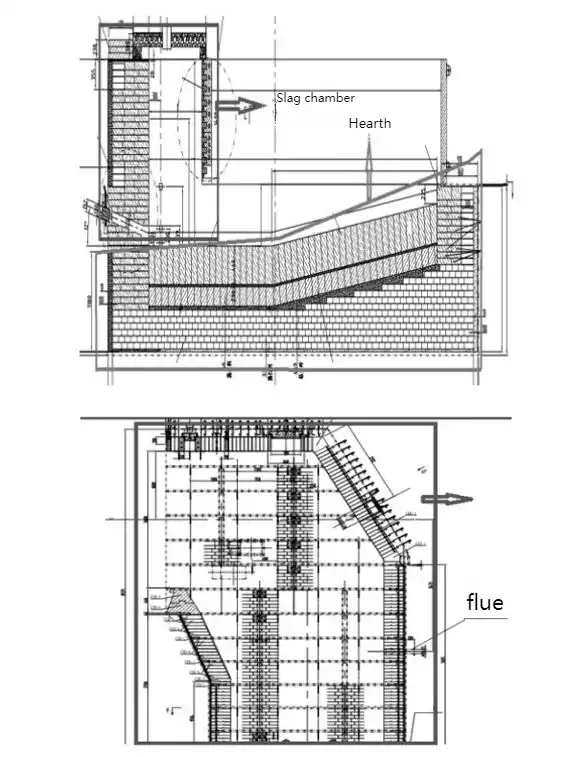

Design of a side blowing furnace for smelting blister copper

The design of the furnace body with side airflow is made according to the type of stationary rectangular furnace, which consists of a copper water jacket, fireproof material and steel structure. The furnace body is divided from top to bottom into four parts: under, furnace body, stove roof and chimney. Under, used for storing blister copper and slag, formed as a result of the reaction, made of refractory bricks, and at the end of the hearth a slag chamber is installed to separate the copper slag.

The furnace body is divided into a reaction zone and a flue gas zone. The reaction zone consists of a copper water jacket and a primary lance, and the flue gas zone consists of a slotted copper water jacket and a secondary lance to protect against slag deposits. The reaction exhaust gas is discharged from the flue gas outlet, formed by a water jacket, and goes into the chimney. The size of the flue gas exhaust space is calculated according to the flue gas flow rate, to guarantee, that flue gases remain in the chimney for more 2 seconds. The main reaction zone of the side-flow furnace refers to the protective position of the copper water jacket, and fireproof materials are mainly used in hearth, slag chamber and chimney.

How to choose magnesia-chromium refractories?

Fused recombined magnesia-chromium refractories have the best characteristics, followed by semi-recombined magnesia-chromium refractories. Combined with loss of refractory materials in the hearth, slag chamber and chimney area of the furnace with side airflow in the hearth, the slag chamber and chimney area use semi-recombined, electrofusion-recombined and directly bonded magnesia-chromium refractory materials.

Rongsheng Refractories Group

Rongsheng Refractories Group